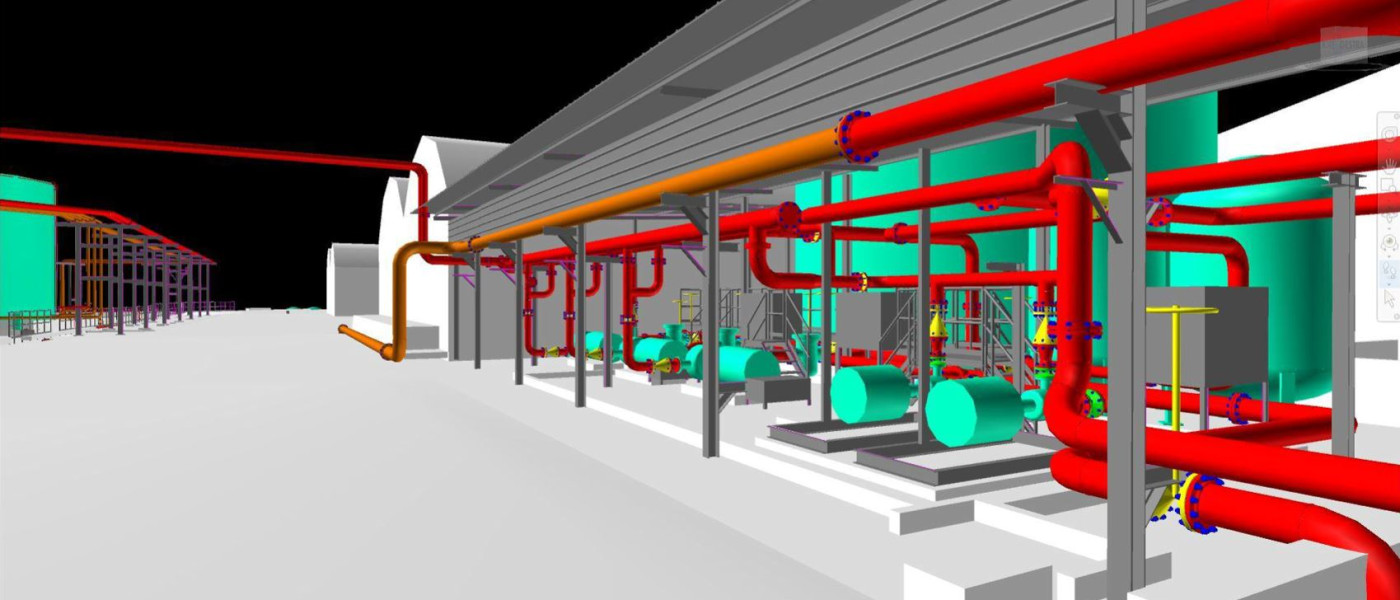

3D LASER SCANNNIG SURVEY for Coastal Fuel Storage Plant

-

Client cliente italiano

-

Location Italia

-

Timing 2020

PROJECT’S GOAL:

The Client, a leading Italian Operator in fuel storage and distribution, needed to define a “Point 0” of all Plant system (fuels distribution network, fire system, water treatment, drain and utilities) which have undergone substantial changes, over time, not always reported in Site documentation.

Techfem suggested a 3D Laser Scanning Survey to be executed to capture the existing conditions and As-is informations of the Facility and create an intelligent 3D Model.

OUR APPROACH

The first step in project execution workflow involved capturing the existing Facility.

Inspection and Survey activities were carried out combining a GPS Topographic Station and a Laser Scanner device. Once a Primary Reference Network (GPS) was define, Scan points where individuated within the Plant area to return the entire complex of equipments, civil works, steel structures and pipes in order to avoid shadow cones. Each Scan has been georeferenced in Post Processing activities using “Cloud to cloud” method with the aim of generating a complex Point Cloud that contained the information of entire Plant. Basic measurements and coordinate checks were performed to verify that the Point Clound was correctly orientated and positined within the Plant Coordinate System. All the Data has been organized in an electronic Database avaible for Client consultation.

The next step was to import the existing Point Cloud to 3D Modeling Tools where a detailed 3D Model of the existing facility could be created. The 3D Model is characterized and contains the information (piping classes, line numbers, weights, tag, steel profiles, etc.) detected during the Inspection and returned according to the Company’s STDs.

CLIENT BENEFITS

- Quickly define a” Point 0” of all Plant system;

- Share a Tool (Clouds Database and intelligent 3D Model) allowing to:

- Visualize, measure and interrogate all Plant system from different remote workstation;

- Check or Plan future Revampings;

- Identify areas for new projects;

- Calculate volumes (containment basins, tanks, etc.);

- Share information with Suppliers and/or Engineering Companies;

- Optimize the workflows during the Design phase between the involved disciplines (Mechanical, Civil, Electro-Instrumental, HSE, etc.)

- Reduction of Site inspections or Surveys;

- Optimization of timing and coasts for Design Activities;

- Manage a Database as complete as possible;

- Extract 2D Documentation (As built) such as P&ID, layouts, arrangements, isometrics, MTO, etc.

- Perform calculations checks and sizings

- 16.05.2022

- |

- 14.51